When it comes to classic Chevy engines, few things stir the soul quite like the throaty roar of a well-tuned powerplant. If you’re lucky enough to be working on a Holley 12 327 13, you’re in for an electrifying experience. Imagine dusting off those hidden gems in your garage, taking that rusty carburetor, and breathing new life into it—sounds like a tall order, right? But fear not! Rebuilding your Holley carb isn’t just reserved for the pros who wear grease stains like badges of honor. With the right guidance, a bit of elbow grease, and maybe a few cups of coffee, you could be the one at the helm, transforming that old piece of metal into a masterpiece. So, let’s roll up our sleeves and dive into the nitty-gritty of revitalizing your Chevy and making it purr like a kitten again!

Revamping the Heart: Essential Tools for Your Holley 12 327 13 Rebuild

Getting your hands dirty is part of the joy of rebuilding your Holley 12 327 13, right? To kick things off, you’ll want to make sure you gather the essential tools for this undertaking. Think of it like a chef assembling ingredients: you can’t bake a cake without flour! Here’s a quick checklist to keep you on the right path:

- Socket Set: Nothing beats a reliable socket set for those tight spaces.

- Screwdrivers: Both flathead and Phillips, because, you know, not all screws are created equal!

- Torque Wrench: This ensures everything is tightened just right—like a snug hug for your parts.

- Gasket Scraper: Say goodbye to old gaskets with this handy tool.

But wait, there’s more! Once you’ve got the basics, let’s talk about some specialized gear that you might want to invest in. Having the right equipment can make your project smoother than a fresh pot of honey:

| Tool | Use |

|---|---|

| Digital Caliper | Precision measurements for smooth fitment. |

| Cleaning Brushes | For making those parts shine like new. |

| Fuel Pressure Gauge | Monitor your setup’s heart rate—it’s crucial! |

Decoding the Carb: Understanding Holley 12 327 13 Components and Their Function

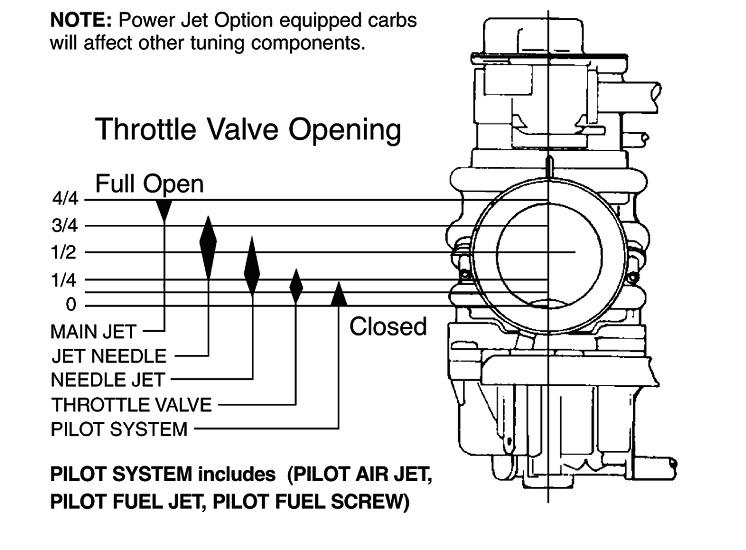

When diving into the world of the Holley 12 327 13, it’s crucial to familiarize yourself with its main components. Think of the carburetor as the heart of your Chevy, pumping the right fuel-air mixture to the engine’s veins. The float bowl acts like a reservoir, ensuring there’s always a steady supply of fuel on hand, while the jets control the flow, dialling in just the right amount for optimal performance. The venturi is your carb’s little magic zone, where the air speeds up and creates a vacuum to draw in fuel. Don’t forget the accelerator pump, which gives that quick burst of fuel when you hit the gas – it’s like having a nitro boost when you need it most. The synergy between these parts is what transforms a lackluster engine into a roaring beast!

Understanding how these components work together can make a massive difference in performance. Adjusting the idle mixture screws ensures your engine runs smoothly at lower speeds, just as seasoning makes a dish shine. The power valve kicks in when you’re really pushing the throttle, giving the engine a hearty injection of fuel to maintain power during acceleration. To take it a step further, consider the choke mechanism; it’s like a cozy blanket for cold starts, keeping the air-fuel mix rich until the engine warms up. Knowing the ins and outs of the Holley 12 327 13 will not only help you troubleshoot issues but ensure your rebuild brings your Chevy back to life in a way that’s as smooth as butter!

Tuning Secrets: Fine-Tuning Your Rebuilt Carb for Peak Performance

Tuning your rebuilt Holley carb is like putting the final touches on a masterpiece—every little detail counts. To get the most out of your Chevy, you’ll want to focus on a few essentials that can really amp up your performance. Start with the fuel mixture: a balanced air-to-fuel ratio is crucial for optimal combustion. If your engine feels sluggish, adjusting the idle mixture screws can bring it back to life. Think of it as fine-tuning a musical instrument; a slight tweak here and there can transform the whole sound. Don’t overlook the importance of float level either. Too high or too low, and you might as well be playing a broken record—your engine won’t run smoothly. Keep that float right at the midway point to promote steady fuel flow and prevent surging during acceleration.

Next up is the accelerator pump—this little component is like that secret ingredient in grandma’s cookie recipe that takes it to the next level. If you find hesitation when you hit the gas, a quick pump adjustment can often correct it. Additionally, be mindful of the secondary springs in your carb. These springs help control when the secondaries open, which can feel akin to turning on the jets in a rollercoaster; too quick and you’ll stall, too slow and you’ll lose speed. A simple swap to a spring with a different tension can have you zooming past the competition. And for those who love precision, keeping track of your jet sizes in a neat little chart can simplify changes when tuning for various conditions, ensuring you’re always ready for whatever the road throws at you.

Common Pitfalls to Avoid: Navigating Challenges in Your Rebuild Journey

When diving into the rebuild of your Chevy, it’s easy to get overwhelmed by excitement, but that enthusiasm can sometimes cloud your judgment. A really common pitfall is skipping your research—assessing the parts you need, the right techniques, and understanding the quirks of the Holley 12 327 13. Make sure you:

- Consult reputable sources—books, online forums, or even local car clubs.

- Document every step—take notes or photos throughout the process.

- Don’t rush it—patience is key; a hasty rebuild often leads to mistakes.

It’s like trying to bake a cake without measuring the ingredients; you might think you’re doing it right, but the end result could be a disaster.

Another major mistake to avoid is neglecting your tools. Quality matters when you’re working on your engine. Invest in the right gear to prevent unnecessary wear and tear on both you and your precious machine. Consider the following essentials:

- Torque wrench—to get those specs just right.

- Socket set—you’ll need various sizes for different bolts.

- Engine hoist—lifting that engine block solo isn’t as fun as it sounds.

Using subpar tools is like trying to paint a masterpiece with a brush made of straw; it just won’t turn out the way you envisioned. Keep your work area organized and your tools in excellent condition, and you’ll notice the difference in your rebuild experience.

In Conclusion

So, you’ve navigated the twists and turns of reviving your Chevy by rebuilding that Holley 12 327 13. Kudos to you! It’s like breathing new life into a classic; you’re not just tinkering under the hood—you’re making memories. Each bolt you tightened and each gasket you replaced is a step toward hitting the open road with a ride that runs smoother than ever.

As you slide behind the wheel, imagine the rumble of your engine harmonizing with the thrill of the journey ahead. Whether it’s a weekend cruise or a cross-country adventure, your Chevy is more than just a vehicle; it’s a canvas for your passion. So, stay curious, keep learning, and don’t shy away from getting your hands dirty again. There’s always another project on the horizon.

Thanks for joining me on this rebuilding adventure! Here’s to all your future drives being filled with power, nostalgia, and, of course, a bit of that sweet, sweet engine music. Happy cruising!