Imagine you’re standing in front of a double acting hydraulic cylinder, ready to dive into a project that promises power and precision. But wait—before you unleash its full potential, you need to master the art of bleeding it. Why? Because trapped air can turn your hydraulic system from a well-oiled machine into a sputtering mess. Think of it like trying to brew a perfect cup of coffee with stale beans; you won’t get the rich flavor you crave. Exploring the ins and outs of bleeding a double acting hydraulic cylinder isn’t just essential; it’s a skill that can save you time, headaches, and ultimately, money. So roll up your sleeves and let’s demystify this crucial process together!

Understanding the Mechanics of Double Acting Hydraulic Cylinders

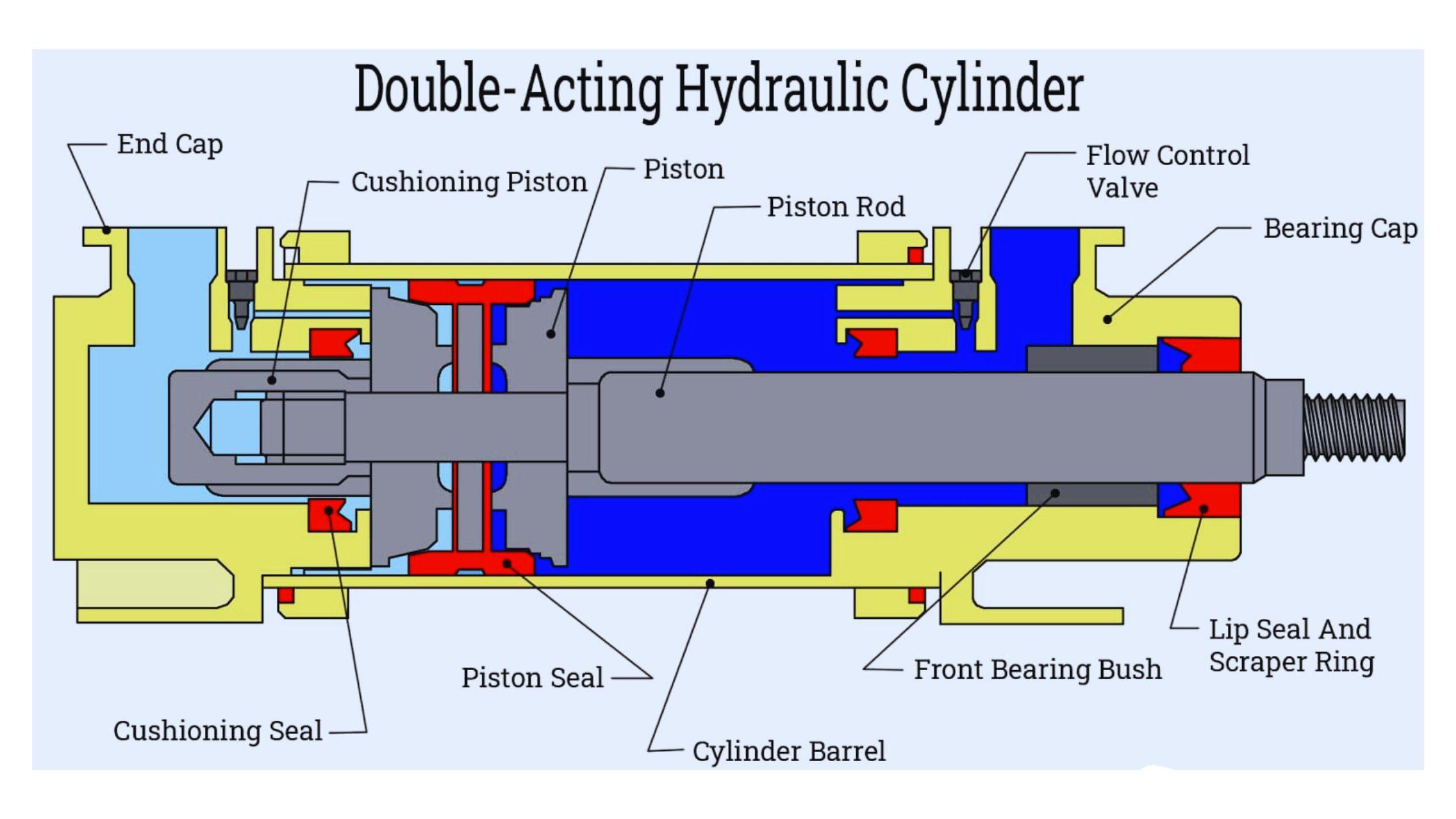

Double acting hydraulic cylinders are the unsung heroes of many hydraulic systems, providing power in both directions by using pressurized fluid. Unlike their single-acting counterparts, these cylinders can push and pull, allowing them to accomplish tasks more efficiently. Think of them as a reliable two-way street, where fluid enters through one port to extend the cylinder and another port to retract it, facilitating smooth operation in various machinery. The key to their effectiveness lies in the precise control of hydraulic fluid, which can make or break a project when it comes to operating heavy machinery or vehicles.

In mastering the art of bleeding these cylinders, it’s essential to understand a few vital components: air entrapment, fluid levels, and valve positioning. When air sneaks into the system, it can cause lag or inconsistent operation, sort of like trying to swim with a pocket full of stones. To tackle this, regularly check the fluid levels and ensure your valves are correctly positioned to minimize pressure loss and prevent air pockets. Here’s a quick reference table to guide you through bleeding procedures:

| Step | Action |

|---|---|

| 1 | Check hydraulic fluid levels. |

| 2 | Loosen the bleed screw. |

| 3 | Extend the cylinder to release air. |

| 4 | Tighten the bleed screw once fluid flows without bubbles. |

| 5 | Test the cylinder operation. |

Essential Tools and Supplies for a Smooth Bleeding Process

To make your bleeding process as smooth as butter, you’ll need a handful of essential tools and supplies at your side. First up, gather your wrenches or socket set for those stubborn hydraulic fittings. A bleeding kit is essential — make sure it comes with hoses and fittings that fit snugly on your bleed ports; you don’t want any air sneaking back into your system. Also, keep a supply of hydraulic fluid handy; it’s like the lifeblood of your cylinder. Don’t forget the rags or absorbent pads for any spills because, let’s face it, messes happen! Lastly, a clear container to catch the old fluid lets you see what you’re working with, ensuring nothing escapes unnoticed.

Now, let’s talk about a few extra goodies that can take your bleeding game to the next level. An independent hydraulic pump can be a lifesaver, especially if you often work solo—it allows for more precise control without needing a second pair of hands. Some folks swear by a pressure gauge for that extra reassurance that your system is running at optimal levels. And if you’re feeling a little fancy, consider using colored hydraulic fluid in your feedback container; it’s not just stylish, it makes spotting air bubbles a breeze! Here’s a quick look at what you really shouldn’t skip:

| Tool/Supply | Purpose |

|---|---|

| Wrenches/Socket Set | Loosening and tightening fittings |

| Bleeding Kit | Essential for proper bleeding |

| Hydraulic Fluid | Essential fluid for operation |

| Rags/Pads | Clean up any spills |

| Pressure Gauge | Monitor hydraulic levels |

Step-by-Step Guide to Efficiently Bleed Your Hydraulic Cylinder

Bleeding your hydraulic cylinder doesn’t have to be a daunting task. Start by ensuring your safety and the cylinder’s integrity. First, check the hydraulic fluid level in the reservoir; it should be at the appropriate mark to avoid air being reintroduced during the process. Next, connect the hoses properly: the inlet to the pump and the outlet to your cylinder. Make sure everything is tight to prevent leaks—think of it like sealing your drink bottle before a long hike; you don’t want any spills on the way!

Now comes the fun part. With the system powered up, slowly cycle the cylinder through its full range of motion. While doing this, keep an eye on the release valve—you want to crack it open gently when the cylinder reaches its fully extended position. This is where trapped air escapes like a stubborn cork popping out of a wine bottle. Once you notice a steady stream of fluid without bubbles, it’s like finally eliminating that pesky lump in your favorite mashed potatoes. Now, tighten everything up, and you’re good to go!

Preventive Tips to Maintain Optimal Cylinder Performance

To keep your hydraulic cylinder operating smoothly, regular maintenance is key. Start by inspecting seals and hoses periodically for wear and tear. It’s like checking the health of a car engine; if there’s a problem, it can cause big issues down the line. Make sure to clean the cylinder regularly to prevent dirt and debris from entering the system, which could lead to performance hiccups. Additionally, keep an eye on the fluid levels—just like you wouldn’t let your car run low on gas, a hydraulic system needs the right amount of fluid to function correctly.

Another important aspect of maintenance is to monitor performance and listen for unusual noises. If your cylinder starts acting up or sounds odd, don’t ignore it! Quick intervention can mean the difference between a minor fix and a major overhaul. Establish a routine for bleeding air from the system to eliminate any potential air pockets that can compromise your cylinder’s efficiency. It’s the equivalent of clearing your throat before delivering a speech—smoothing out those little disturbances can help everything run like a well-oiled machine!

Wrapping Up

And there you have it! You’ve now unlocked the secrets to mastering the art of bleeding a double-acting hydraulic cylinder. It’s like tuning a fine instrument; with the right adjustments, you can ensure your machinery operates smoothly and efficiently. Remember, taking the time to do this properly not only enhances performance but significantly extends the life of your equipment.

So, the next time you’re faced with the challenge of trapped air causing hiccups in your hydraulic system, you’ll be armed with the know-how to tackle it head-on. Keep your tools at the ready, and don’t shy away from a little elbow grease – your hydraulic system will thank you for it! Dive in, get your hands dirty, and experience the satisfaction of a job well done. Happy bleeding!